Dear Jason and all,

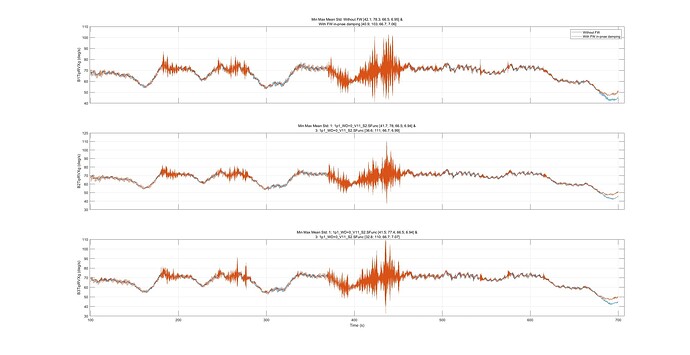

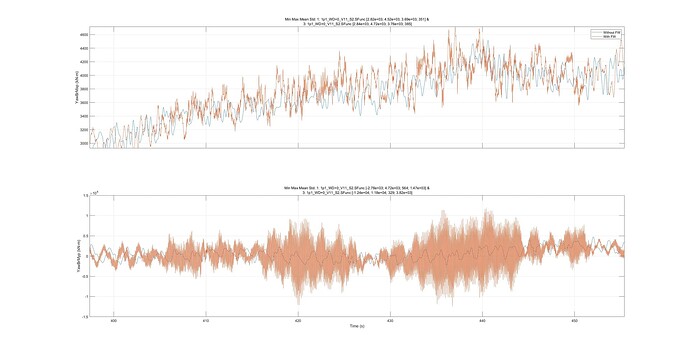

Let me walk you through my findings with the help of some plots, as they may provide insights into the issue at hand. Below you see results from a typical 600-second simulation of one DLC.

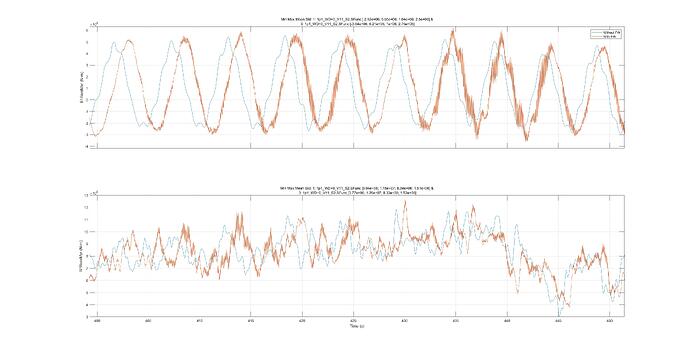

Initially, all blades are charged with the FW. By design, the FW discharges, and in some cases—depending on the available wind capacity—it also charges again. In this particular case, charging is rare due to the low wind regime.

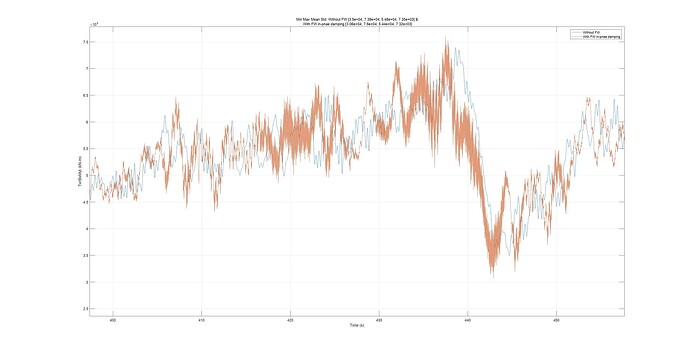

However, frequent discharge cycles are evident between 400 and 450 seconds. Therefore, in the following figures, I will focus on this specific region.

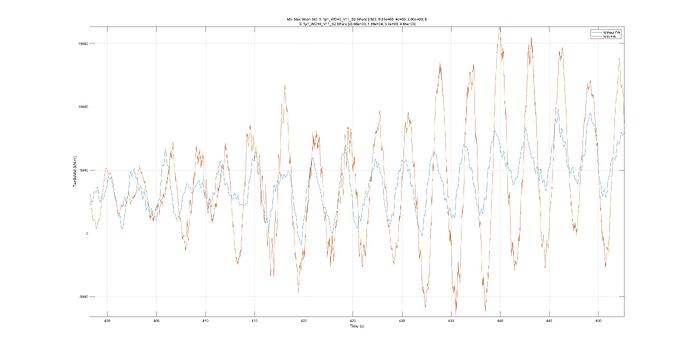

The individual blade in-plane speeds:

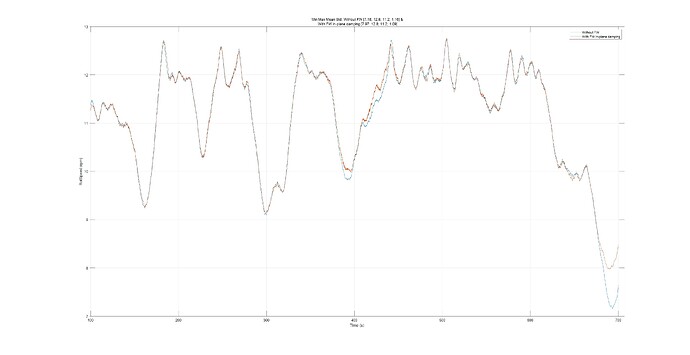

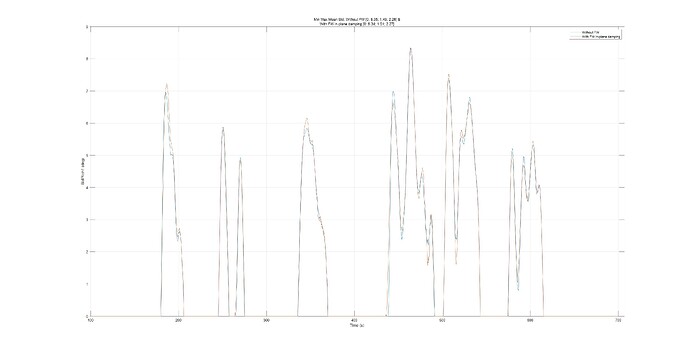

The collective rotor speed clearly shows a lower standard deviation.

Since the pitch angle between 400 and 420 seconds is zero, the observed increment in rotor speed can be attributed directly to the Coriolis effect of the FW.

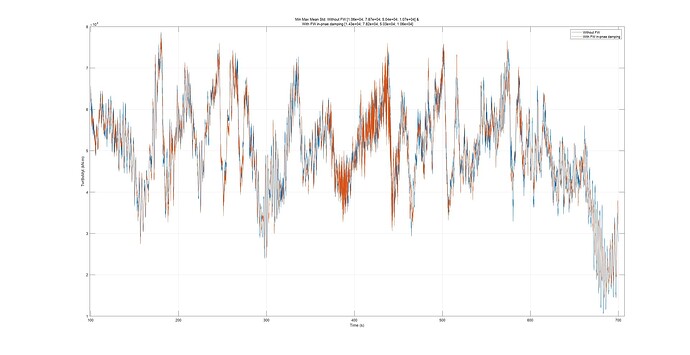

Moving to the fore-aft bending moment, you can observe that both the mean value and the standard deviation are reduced when the FW is active.

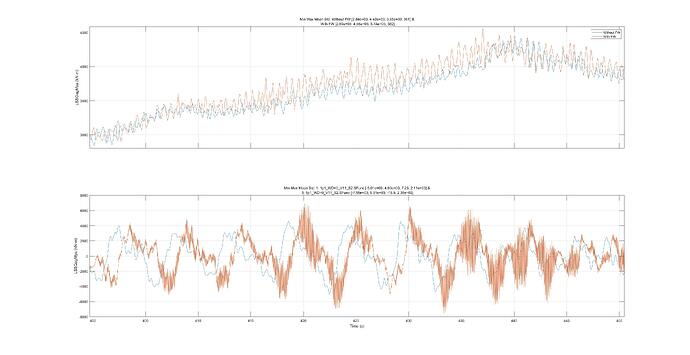

To extend this finding, I performed the entire DLC 1.2 with NTM and calculated the fatigue loads. The following results summarize the fore-aft bending moment for different Wöhler slopes:

Wöhler slope: 3 4 5

without FW: 60627.42 54773.38 53195.35

With FW: 55050.74 49820.65 48681.21

Thus, not only in this single case but overall, the fatigue load in the fore-aft direction is consistently reduced due to the damping effect.

My main question is: why does damping the in-plane blade oscillations result in a reduction of the tower structural loads in the fore-aft direction? Any insights you can provide in connecting these effects would be greatly appreciated.

Best Regards

Abhinay Goga