Dear Jonkman,

I hope you are doing well.

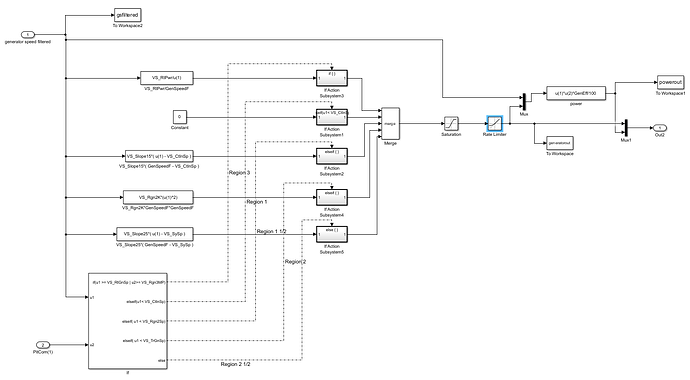

I tried to test the 5MW baseline controller, but the pitch controller or torque controller is not responding. Can you please have a look and see what mistake did I make??

I guess the blocks are fine, but the values might wrong.

And these are my set up:

CornerFreq = 1.570796325;

PC_DT = 0.00125;

PC_KI = 0.008068634;

PC_KK = 0.109996;

PC_KP = 0.01882681;

PC_MaxPit = 1.570796;

PC_MinPit = 0.05;

PC_MaxRat = 0.1396263;

PC_RefSpd = 122.9096*(pi/30); %in rad

R2D = 57.295780;

RPS2RPM = 9.5492966;

VS_CtInSp = 70.16224;

VS_DT = 0.00125;

%VS_MaxRatFORHIGHWIND = 30000.0;//Tried to change but irrelevant

VS_MaxRat = 15000.0;

VS_MaxTq = 47402.91;

VS_Rgn2K = 2.332287;

VS_Rgn2Sp = 91.21091;

VS_Rgn3MP = 0.01745329;

VS_RtGnSp = 121.6805;

VS_RtPwr = 5296610.0;

VS_SlPc = 10.0;

GenEff = 94.4;

fc = 0.25;

alpha = exp(-2piDT*fc);

VS_SySp = VS_RtGnSp/( 1.0 + 0.01*VS_SlPc );

VS_Slope15 = ( VS_Rgn2KVS_Rgn2SpVS_Rgn2Sp )/( VS_Rgn2Sp - VS_CtInSp );

VS_Slope25 = ( VS_RtPwr/VS_RtGnSp )/( VS_RtGnSp - VS_SySp );

if VS_Rgn2K == 0.0

VS_TrGnSp = VS_SySp;

else

VS_TrGnSp = ( VS_Slope25 - sqrt( VS_Slope25*( VS_Slope25 - 4.0VS_Rgn2KVS_SySp ) ) )/( 2.0*VS_Rgn2K );

end

Can you please help with this issue?

Dear @Hyeon.Cha,

I haven’t reviewed the details of your Simulink model, but it looks like the OpenFAST S-Function is returning zeros for the pitch angle and generator torque commands from ServoDyn. Have you set up your ServoDyn model to receive the pitch and torque signals from Simulink (PCMode = VSContrl = 4, TPCOn = 0 s, GenTiStr = GenTiStp = TRUE, TimeGenOn = 0 s, TimGenOf > TMax)?

Best regards,

Dear Jonkman,

Thank you for your reply.

I checked the values you mentioned and it was same.

But I have solved the problem ! and would like to ask if these values for NREL 5MW OC3 spar are appropriate:

PC_KI = 0.008068634; % [1/s^2] - Integral gain for pitch controller

PC_KK = 0.109996; % [-] - Gain scheduling coefficient (used in some formulations)

PC_KP = 0.01882681; % [1/s] - Proportional gain for pitch controller

Best regards,

Hyeon

Dear @Hyeon.Cha,

I’m glad you solved your original problem.

I agree with your value of PC_KK. Your values of PC_KI and PC_KP are the values used for the land-based NREL 5-MW baseline wind turbine, but these values were lowered for the NREL 5-MW baseline wind turbine atop the OC3-Hywind spar. As documented in the OC3-Hywind specifications document (https://docs.nrel.gov/docs/fy10osti/47535.pdf), the values should be PC_KI = 0.008965149 and PC_KI = 0.006275604 s. Note that your units on PC_KI and PC_KP are not shown correctly either.

Best regards,

Dear Jonkman,

Thanks for the information. I really apperciate it and the response is much better now.

My goal is to test in extreme wind conditions ( above 25 m/s), but whenever I put 35 the simulink stops and says FAST_Solution:FAST_UpdateStates:FAST_AdvanceStates: NaN state detected.

** MD_UpdateStates: NaN state detected.**

Can you please tell me how to address this issue and test in extreme weather conditions?

Best regards,

Hyeon

Dear @Hyeon.Cha,

For this above cut-out condition, have you disabled the pitch and torque controller in ServoDyn, idled the rotor with the blades feathered in ElastoDyn, and the disabled the wake and unsteady airfoil aerodynamics in AeroDyn?

Best regards,

Dear Jonkman,

Thank you for the information.

Can I ask if the Discon_OC3Hywind.dll can do the individual pitch control?

In the Servodyn.dat file I can see the “Ptch_Cntrl - Record 28: Use individual pitch control {0: collective pitch; 1: individual pitch control} (switch) [used only with Bladed Interface]”

and I wonder if also Discon_OC3Hywind.dll provide individual pitch control.

I downloaded the precompiled version in OpenFAST Github Asset and using.

Also I would like to know if the DISCON_OC3Hywind.dll can do IPC, then can I simulate all different scenarios? as shown below?

If DISCON can control IPC, VC Mode 5, PC Mode 4 and if DISCON can only do CPC, VC Mode 5 and PC Mode 4

I’m bit confused if the system can calculate properly when the VC and PC mode are different. And looks like the PC Mode 5 and VC Mode 4 is inappropriate, since the Pitch Controller (DISCON) will not use torque from simulink and will calculate the torque by own logic.

Best regards,

Hyeon

Dear @Hyeon.Cha,

The baseline controllers provided for the NREL 5-MW baseline wind turbine (including DISCON.dll, DISCON_OC3Hywind.dll, and DISCON_ITIBarge.dll) do not include support for IPC. You’d have to modify the source code or upgrade from the baseline controllers to ROSCO (GitHub - NREL/ROSCO: A Reference Open Source Controller for Wind Turbines) if you wish to consider IPC for the NREL 5-MW baseline wind turbine models.

The baseline controllers for the NREL 5-MW baseline wind turbine, as well as ROSCO, have both pitch and torque controller supported by the same DISCON library. So, if you enable the controller through PCMode = 5 or VSContrl = 5, I would also enable the other to avoid issues whereby part of the control is not functional.

Best regards,

1 Like

Dear Jonkman,

Thank you for your help.

I am currently working on a project where I am developing a reinforcement learning-based pitch controller (using Proximal Policy Optimization, PPO) for a floating wind turbine. For this purpose, I am using OpenFAST in combination with Simulink.

To train the PPO agent, I need to run many simulation episodes. After each episode, it is essential to reset the OpenFAST simulation so that each run starts from the initial condition (e.g., time = 0, same wind and sea states).

I understand that OpenFAST has a reset functionality, including options such as init, trueRestart, and restartDriverInitFAST. I would like to confirm:

- Is there a supported or recommended way to reset OpenFAST through Simulink (e.g., via the S-Function) after each episode, such that it behaves as if the simulation started from scratch (like using

init)?

- Or would you recommend reloading the Simulink model (e.g., using

sim() in a MATLAB loop) to ensure OpenFAST fully restarts at each episode?

Any guidance or best practices for using OpenFAST with reinforcement learning frameworks would be greatly appreciated.

Best regards,

Hyeon

Dear @Hyeon.Cha,

I’m not familiar with the functions you mention, but in the FAST library called by the OpenFAST S-Function, there is a routine FAST_End() in source file FAST.Library.f90, which is called by function mdlTerminate() in source file FAST_SFunc.c that is part of the OpenFAST S-Function. As long as FAST_End() is called and executs without error, the next simulation should start with its normal initialization.

Best regards,

Dear Jonkman,

Thank you. I found the way to restart it.

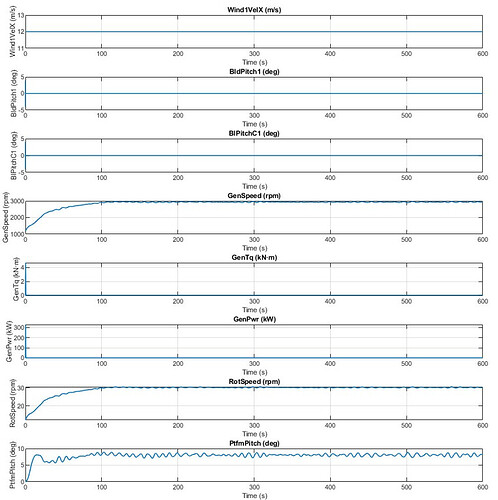

While I was analyzing the outdata, the wind speed moves so quickly and also the blade pitch.

Wind Speed Time

42.51762009 2.375

39.97005463 2.4375

38.82161331 2.5

38.90948105 2.5625

38.91971207 2.625

etc..

I have applied a Rate Limiter block in Simulink before sending the pitch command to OpenFAST, with a limit of ±0.1396 (in rad), and the simulation timestep is 0.0625 seconds.

Given this setup, I assume that the actual pitch command change per step (as applied in OpenFAST) should not exceed:

0.1396×0.0625=0.008725 rad/step0.1396 \times 0.0625 = 0.008725 \text{ rad/step}0.1396×0.0625=0.008725 rad/step

My question is:

Does OpenFAST receive and apply the Simulink pitch input exactly as-is every time step, or is there any internal mechanism that might affect the pitch response (e.g., additional filtering, interpolation, or actuator dynamics)?

Or Should I multiply DT with Max and Min Rat?

I would like to confirm whether this per-step rate limit is strictly enforced in OpenFAST when using Simulink-based pitch control (PCMode = 4).

And also for the wind that generated from turbsim. It changes so quickly and wonder if it is possible to change 1-3 wind/0.0625 s. Seems not realistic changes.

Best regards,

Hyeon

Dear @Hyeon.Cha,

The OpenFAST S-Function will use extrapolated values of the inputs (including blade pitch) passed from Simulink (as discussed in other forum topics e.g.: S-Function input output signal mismatch). Thus, the OpenFAST S-Function may not report exactly the same values of the blade pitch that are input from Simulink and the control signals should be smooth, without steps.

I’m not sure I understand your question about wind steps, but I’m a bit puzzled by your wind data anyway because I would not expect the rotor to be operational at such high wind speeds.

Best regards,

Dear Jonkman,

Hello,

I am developing a pitch controller for a floating offshore wind turbine that must operate under extreme weather conditions. The reference wind speed UrefU_{\text{ref}}Uref is around 36 m/s with a turbulence intensity (TI) of approximately 16%.

My primary control goal is to keep the rotor speed within 0 to 1.267 rad/s. However, during high-wind simulations, I observe that the rotor speed fluctuates rapidly, with significant angular acceleration.

I would like to ask the following:

- How exactly is

RotorSpeed calculated in OpenFAST?

Is it derived from the azimuth angle’s time derivative, and does OpenFAST consider the rate of change (acceleration) of the rotor speed when computing RotSpeed?

- If the rotor speed fluctuates rapidly (i.e., high

dω/dt), does OpenFAST reflect this dynamic response accurately in its outputs?

- Is there any recommended or allowable range for the rotor acceleration (

dω/dt) for the NREL 5MW baseline turbine or similar models?

Any documentation reference or clarification would be greatly appreciated.

Thank you!

Dear @Hyeon.Cha,

The rotor speed is calculated in ElastoDyn as the integral of the rotational acceleration. Yes, rotor speed fluctuations and their impact on structural loads should be accurately captured by OpenFAST. There are no specific rotational acceleration limits specified for the NREL 5-MW baseline wind turbine, but the higher the acceleration, the higher the structural loads would be, which would be a limiting factor.

FYI: The cut-out speed for the NREL 5-MW baseline wind turbine is 25 m/s, so, your case sounds extreme, with winds well beyond cut-out. Are you considering some soft cut-out control option?

Best regards,

Dear Jonkman,

Thank you for your help.

I found that the hub-height of NREL 5MW OC3 Hywind Spar is 90m on the “Definition of the Floating System for Phase IV of OC3” document. But in the OpenFAST file, the default of NREL 5MW OC3 Hywind Spar is 87.6 TowerHt and TowerBsHt in the ElastDyn.dat file, which is saying 97.6m.

**87.6 TowerHt - Height of tower relative to ground level [onshore], MSL [offshore wind or floating MHK], or seabed [fixed MHK] (meters), 10 TowerBsHt - Height of tower base relative to ground level [onshore], MSL [offshore wind or floating MHK], or seabed [fixed MHK] (meters)**

I would like to generate the wind through TurbSim, but which hub-height should I use? and should I consider the hub-height as 97.6?

Best regards,

Hyeon

Dear @Hyeon.Cha,

Hope you are doing well.

I am Riad, a wind turbine enthusiast.

Regarding the hub height of the 5 MW spar, it is 90 m.

The tower base is 10 m above sea level.

The effective tower height = 87.6 -10 = 77.6 m.

The hub height = Tower_height_from _sea_level + Distance_from_tower_top_to_rotor_shaft + Overhang * sin(shaft_tilt) = 87.6 + 1.96256 + 5.0191*sin(5_degrees) = 90 m

Best Regards,

Riad

2 Likes

Dear Riad,

Thank you for your explanation. And thank you for wonderful equation also !

Best regards,

Hyeon

1 Like

Dear Jonkman,

I am building a blade pitch controller using reinforcement learning for the NREL 5MW OC3 Hywind Spar type, which is designed to maintain platform stability during extreme weather conditions.

In the paper “Definition of the Floating System for Phase IV of OC3,” it states that “The surge and sway displacements (q1 and q2) were varied from −36 to 36 m in steps of 6 m. The heave displacement (q3) was varied from −12 to 12 m in steps of 4 m.” I would like to understand if the ±36 m and ±12 m ranges were chosen because they represent the maximum displacements that the mooring cables can withstand.

Also, while running OpenFAST simulations, I occasionally encounter error warnings. Do these errors occur if the mooring cables are damaged or broken during the simulation?

Thank you for your time, and I look forward to your response.

Hyeon

Dear @Hyeon.Cha,

The mooring motion ranges from the paper you cite were selected to be beyond the possible range of motion of the OC3-Hywind spar under any condition where the mooring system remains intact.

MoorDyn v2 has an option to simulate a mooring line loss at a user-specified time or if the instantaneous tension exceeds a user-specified limit. But other than that, it is not possible in any mooring module of OpenFAST to lose a mooring line.

Best regards,

1 Like

Dear Jonkman,

Hello,

While checking the Kp and Ki values in the documents, I found the following: Kp = 0.006275604 s, Ki = 0.0008965149, and KK = 0.109996. However, the documents state that the P and I values are given for the minimum blade-pitch setting. I am wondering if it is okay to use these values as they are. Does this mean that I can only use them when the blade pitch angle is 0°?

I would like to run the PI controller when the wind speed is rated wind speed as I’m comparing the responses with my designed pitch controller and the baseline controller

Best regards,

Hyeon Cha