Hello everyone.

Currently, I’ve been testing FEAMooring for 15 MW FOWT. According to the “Verification and Validation of the New Dynamic MooringModules Available in FAST v8” report, the simulation results of FEAMooring and Moordyn should be the same under the condition of the same total number of elements per line. However, after a few attempts, the results seems to be totally different.

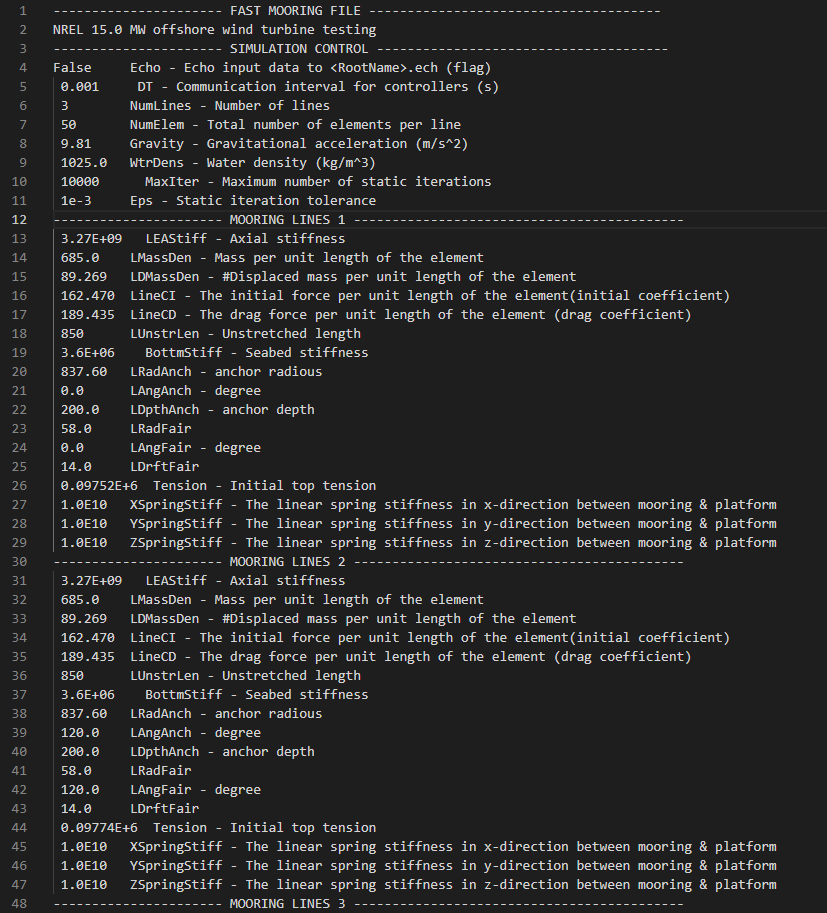

Here is my FEAMooring input file, which I modified from the official IEA_15_240_RWT MoorDyn file.

Could anyone help me with my problem?

Best Regards,

PoChuan

Dear @PoChuan.Mao,

Can you clarify how different the results are between FEAMooring and MoorDyn?

Also, I see how you derived LDMassDen and LineCI from the MoorDyn properties, but I can’t see how you calculated LineCD (I calculate 341.325 (N/m)/(m/s)^2); can you clarify?

Also, I haven’t verified your Tension, but does this represent the initial pretension at the fairlead for the undisplaced structure?

Best regards,

Dear @Jason.Jonkman ,

Thank you for your reply.

The result of the differences between FEAMooring and MoorDyn is showing down below.

The fairlead tension of line 1 was totally different.

LineCD was calculated using the formula (density of water)

Cdtdline/2, which is based on the

Verification and Validation of the New Dynamic Mooring Modules Available in FAST v8.

Cdt denotes the transverse mooring line drag coefficient, while dline is the diameter of the mooring line, which is 0.333m. Density of water is 1025 (kg/m^3).

Tension was calculated by MoorDyn as the initial tension. The result should be 2.436E+06. However I tested 2.436E+06 and 2.436E+06*0.04.

Are there any misunderstandings in the above information?

Best Regards,

PoChuan

Dear @PoChuan.Mao,

Indeed the comparison is quite different.

I agree with your equation for LineCD; perhaps we are just using different drag coefficients? I used Cd = 2 from the MoorDyn file of the UMaine semisubmersible model.

Why are you taking 4% of the mooring pretension? Does using Tension = 2.436E6 N provide a more reasonable result from FEAMooring?

Best regards,

Dear @Jason.Jonkman ,

The MoorDyn file I used was down below.

I used Cd = 1.11.

According to the paper I mention previously, it mentioned that setting a smaller pretention can avoid numerical problem in FEAMooring. Hence they set the pretention as 4% of the mean fairlead load. However, I have tried both cases and got the same results.

Best Regards,

PoChuan

Dear @PoChuan.Mao,

Ah, OK; thanks for clarifying.

I was using the value of Cd = 2 from: IEA-15-240-RWT/IEA-15-240-RWT-UMaineSemi_MoorDyn.dat at master · IEAWindTask37/IEA-15-240-RWT · GitHub.

Unfortunately, I’m not sure why the difference between FEAMooring and MoorDyn remain. I don’t have much experience with FEAMooring; at NREL, we generally rely on the use of MoorDyn.

The following forum topic is likely of interest to you: FEAMooring Design. As mentioned in this topic, I would suggest reaching out to Prof. Yoon Hyeok Bae, the developer of FEAMooring and now a professor at Jeju National University in Korea for help with FEAMooring.

Best regards,

Dear @Jason.Jonkman

Thank you for your kind help. I will contact to Prof. Yoon Hyeok Bae for further help.

However, can you help me to clarify parameters in FEAMooring model? According to the FEAMooring guild, The units of LineCI, LineCD are kg/m, kg/m^2 respectively. I’m wondering whether the units of LineCI, LineCD are (kg/m)(m/s), (kg/m)(m/s)^2 respectively. Thank you.

Best Regards,

PoChuan

Dear @PoChuan.Mao,

The stated units are correct. The force per unit length (in kgm/(ms^2) is written as LineCIacceleration and LineCDvelocity^2, where acceleration is in m/s^2 and velocity^2 is in m^2/s^2, so, the units work out as stated.

Best regards,

Dear @Jason.Jonkman ,

Thank you for your clarification.

Another question, in FEAM Final report, the governing equation is indicate down below.

The software requires bending stiffness to solve the governing equation, the the FEAM input file only requires axial stiffness to be entered. Hence, I’m wondering, if FEAM automatically calculates the diameter of mooring and bending stiffness based on the LDMassDen and axial stiffness respectively? If so, I’m curious whether FEAM assumes the mooring to be a solid rod or a chain when calculating the diameter of mooring and bending stiffness?

Best Regards,

PoChuan

Dear @PoChuan.Mao,

The FEAM final report also mentions that the bending stiffness is not accounted for in FEAMooring, which is my understanding as well.

Best regards,

Dear @Jason.Jonkman ,

Thank you for your kind help.

After few attempts, the model works. However, when I change the number of mooring lines from 3x1 to 3x2, something goes wrong with the simulation.

(Not only generator and power, other parmeters were also NaN)

Could you help me figure out this problem?

Best Regards,

PoChuan

Dear @PoChuan.Mao,

I’m not sure what you mean be 3x2 in terms of number of mooring lines (do you mean you are adding an extra line to each fairlead?), but I would guess your model is going unstable and returning NaNs. Is FEAMooring returning physically correct values at time zero?

Best regards,

Dear @Jason.Jonkman ,

3X2 means adding an extra line to each fairlead.

FEAMooring didn’t return the correct values; it returned NaN instead. In this case, I used 149 segments per line, which means 3m in length per element. However, when I changing the number of segment per line from 149 to 89 , which is equivalent 5m in length per element, the simulation won’t encounter the error mentioned above. In 89 segment case, Fairlead tension at time zero was 1.835E+6, while the tension I set in FEAMooring is 1.690E+6. Could you help me understand what led to this result? Also, does this means that FEAMooring has a limitation in its length per element setting?

Best Regards,

PoChuan

Dear @PoChuan.Mao,

If increased a finer mesh results in NaN,s, my guess is that you’d need to change the solver settings in FEAMooring (such as the time step).

I’m not sure I understand the Tension input to FEAMooring to comment on its use. Again, I suggest reaching out to Prof. Yoon Hyeok Bae.

Best regards,

Dear @Jason.Jonkman ,

Sorry for the delayed respond.

II have tested several cases by changing the number of segments and the static iteration tolerance. The result seems that when the tolerance is set too small, such as 10^-6, FEAM fails to calculate the result despite having converged successfully. However, I am unsure of the reason for this situation.

I have already contacted Prof. Hyeok Bae and am awaiting further discussion. Thank you for your help!

Best Regards,

PoChuan

1 Like